Risk Alert for Senior Living Communities

Prevent disastrous lightning losses

With lightning packing up to 100 million volts of electricity, a lightning strike to an unprotected building can be disastrous. When lightning strikes a building, it will travel through the building and wiring until it finds the ground. This extra voltage can travel through electronic equipment and overload it—the type of damage that is often reported by senior living facilities insured by Church Mutual. The heat from the lightning and the heat generated from the resistance it encounters can quickly start a fire.

Create a lightning protection system

When you think about things that are most likely to be struck by lightning in a storm, a senior living facility probably isn’t top of mind. But fire and lightning losses account for nearly one-third of property claims filed by Church Mutual’s senior living facility customers.

- Almost 60 percent of lightning strikes result in either one or all of the following systems being knocked out of service at a senior living facility: fire alarm, security, call service or telephones.

To protect your facility from the frightening consequences of a lightning strike, consider the following:

- Lightning rod system – This system consists of rods at high points on the building connected to metal cables that run down the sides of the building to a point 2 feet to 10 feet below the ground. The lightning is intercepted and directed to the ground without causing damage to the building or its contents.

- Surge protectors – The Institute of Electrical and Electronics Engineers (IEEE) notes that this common form of protection for electronic equipment is widely utilized by both consumer and commercial users but should not be relied upon as the only defense against a lightning strike. Look for a plug-in protector with the Underwriters Laboratories (UL) rating label to ensure that it meets minimum protection requirements. Also consider that higher quality protectors will typically provide higher levels of protection, although they cost more to purchase.

- Unplug electronics – Even with surge protectors, take the extra step to unplug valuable and sensitive electronics, such as computers and sound systems, when not in use or before a storm begins.

- Protect signal lines – Protect wires that extend outside the building. This is an area commonly lacking proper protection as many alarm systems are tied into the telephone lines. Ensure that telephone, fax machine, dial-up and DSL modem lines are connected to plug-in surge protectors. When purchasing a surge protector, look for one with multiple ports to provide circuit protection for all your signal line equipment.

Find the right installer

Total building protection, including lightning rod systems, will require professional installation. Look for a certified contractor. Ask for an Underwriters Laboratories or Lightning Protection Institute certified contractor to install the lightning protection system.

Create a lightning protection system

-

Almost 60 percent of lightning strikes result in either one or all of the following systems being knocked out of service at a senior living facility: fire alarm, security, call service or telephones.

-

Lightning rod system – This system consists of rods at high points on the building connected to metal cables that run down the sides of the building to a point 2 feet to 10 feet below the ground. The lightning is intercepted and directed to the ground without causing damage to the building or its contents.

- Surge protectors – The Institute of Electrical and Electronics Engineers (IEEE) notes that this common form of protection for electronic equipment is widely utilized by both consumer and commercial users but should not be relied upon as the only defense against a lightning strike. Look for a plug-in protector with the Underwriters Laboratories (UL) rating label to ensure that it meets minimum protection requirements. Also consider that higher quality protectors will typically provide higher levels of protection, although they cost more to purchase.

-

Unplug electronics – Even with surge protectors, take the extra step to unplug valuable and sensitive electronics, such as computers and sound systems, when not in use or before a storm begins.

- Protect signal lines – Protect wires that extend outside the building. This is an area commonly lacking proper protection as many alarm systems are tied into the telephone lines. Ensure that telephone, fax machine, dial-up and DSL modem lines are connected to plug-in surge protectors. When purchasing a surge protector, look for one with multiple ports to provide circuit protection for all your signal line equipment.

Find the right installer

Parking lots are more than just first impressions

Your parking lot greets residents and visitors as they approach your facility—its condition and appearance giving them some insight as to the quality of care and professionalism you put into the rest of your operations.

Still, far more than first impressions, parking lot and sidewalk maintenance is an important part of your overall safety plan. Slips, trips and falls account for almost one-fourth of all injuries to employees, residents and guests at senior living facilities each year. Whether it is slipping on ice or tripping in a pothole, parking lots and sidewalks are among the most prevalent places for injuries to your residents and visitors.

- In Illinois, a housekeeper slipped and fell on ice, bruising her lower back, while taking out the trash.

- In Minnesota, a health aide was on her way into work when she slipped and fell on ice, fracturing her left wrist. She is expected to be away from work for several weeks.

From ice to cracks and debris, proper maintenance is key

Take the proper steps to keep the grounds clean, attractive and safe.

- Clear snow/ice – Whenever snow accumulates, immediately clear the snow and ice. Melt the ice with an ice melt throw or, at minimum, use a sand-based cover.

- Walk through lot – Periodically, walk through the parking lot looking for potential hazards, such as loose debris, water or ice.

- Sweep it up – Keep the parking lot and the sidewalk swept of sand and other potential slip hazards in the spring and summertime. This also will help keep your lot clean and attractive.

- Check for cracks – Routinely check the parking lot and sidewalks for cracks and other imperfections. Immediately take steps to fix any problems. If cracks and imperfections are discovered early, applying a rubberized sealant can cost as little as 5 cents per square foot. This type of maintenance can extend the life of a parking lot by seven years.

- Drive-up area – Have a drive-up area close to the main doors for those who have difficulty walking on uneven and slippery surfaces. Sturdy handrails need to be installed on all ramps near the entryway.<p>

- Keep painted lines visible – Keep painted parking space lines, crosswalks, drive-up areas and change in elevation lines maintained. Recoat faded or chipped painted areas.

-

In Illinois, a housekeeper slipped and fell on ice, bruising her lower back, while taking out the trash.

- In Minnesota, a health aide was on her way into work when she slipped and fell on ice, fracturing her left wrist. She is expected to be away from work for several weeks.

From ice to cracks and debris, proper maintenance is key

-

Clear snow/ice – Whenever snow accumulates, immediately clear the snow and ice. Melt the ice with an ice melt throw or, at minimum, use a sand-based cover.

- Walk through lot – Periodically, walk through the parking lot looking for potential hazards, such as loose debris, water or ice.

- Sweep it up – Keep the parking lot and the sidewalk swept of sand and other potential slip hazards in the spring and summertime. This also will help keep your lot clean and attractive.

-

Check for cracks – Routinely check the parking lot and sidewalks for cracks and other imperfections. Immediately take steps to fix any problems. If cracks and imperfections are discovered early, applying a rubberized sealant can cost as little as 5 cents per square foot. This type of maintenance can extend the life of a parking lot by seven years.

- Drive-up area – Have a drive-up area close to the main doors for those who have difficulty walking on uneven and slippery surfaces. Sturdy handrails need to be installed on all ramps near the entryway.

- Keep painted lines visible – Keep painted parking space lines, crosswalks, drive-up areas and change in elevation lines maintained. Recoat faded or chipped painted areas.

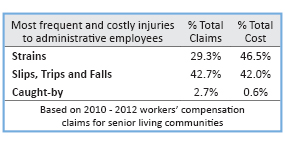

Preventing Injuries to Administrative Employees

Every year, Church Mutual senior living customers report more than 500 injuries to their employees. One occupation needing specific risk management attention is administrative employees.

Employees in this category include directors,executive directors, coordinators and bookkeepers. Past claims provide insight into key safety issues to help prevent similar injuries. Use the following guidelines to help evaluate, develop and implement good risk management practices and procedures for administrative employees:

Lifting Strains

- Instruct employees on proper body mechanics and lifting techniques.

- Arrange work areas so materials are within convenient reaching or lifting distances.

- Eliminate high and low lifting exposures.

- Provide material-handling equipment, such as carts, to limit lifting and carrying objects.

Repetitive Motion Strains

- Rotate staff on jobs that are highly repetitive.

- Conduct ergonomic evaluations of employee workstations.

- Provide chairs, workstations and other office equipment with adjustable options and controls.

- Limit the height of stacked material that leads to awkward lifting and handling postures.

Slips, Trips and Falls

- Maintain clean working areas and walking surfaces to help eliminate slip-and-fall exposures.

- Make housekeeping a top priority. Do not allow boxes to accumulate on floors.

- Require all employees to wear slip-resistant footwear.

- Arrange office furniture, telephone and electrical cords and office supplies to minimize hazards.

Caught-by Accidents

- Secure loose rings or jewelry before operating office equipment.

- Do not operate office equipment without proper covers or guards in place.

- Do not leave file cabinet drawers open. Close them immediately after use.

- Mark or pad obstructions that cannot be removed to help reduce the possibility of direct contact or injury if contact occurs.

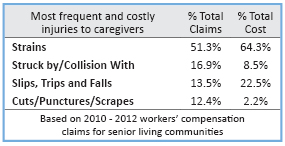

Preventing Injuries to Caregivers

Every year, Church Mutual senior living customers report more than 500 injuries to their employees. One occupation needing specific risk management attention is caregivers.

Employees in this category include CNAs, LPNs and those giving hands-on care to residents. Past claims provide insight into key safety issues to help prevent similar injuries. Use the following guidelines to help evaluate, develop and implement good risk management practices and procedures for caregivers:

Lifting Strains

- Instruct employees on proper body mechanics and lifting techniques.

- Reinforce proper body mechanics for lifting and transferring residents.

- Plan ahead to minimize the number of transfers a resident needs to complete an activity.

- Enforce the two-person lift rule when needed.

Struck by or Collision With Objects

- Place mirrors at corners or other visually obstructed areas to help reduce collisions.

- Place guards over moving parts on heating, cooling, elevator and other equipment to prevent contact.

- Clearly mark and define walkways. Keep carts out of hallways when not in use.

- Mark or pad obstructions that cannot be removed to help reduce the possibility of direct contact or injury if contact is made.

Slips, Trips and Falls

- Design the layout of hallways and rooms to allow smooth traffic flow.

- Keep spill kits available in areas where spills are common. Clean up spills immediately.

- Require all employees to wear slip-resistant footwear.

- Arrange furniture, telephone and electrical cords and supplies to minimize slip-and-fall hazards.

Cuts, Punctures and Scrapes

- Ensure that employees are trained in the safe use and disposal of needles.

- Eliminate the use of needles where safe and effective alternatives are available.

- Modify work practices to make them safer from needlestick injury hazards.

- Dispose of used needles promptly in appropriate sharps disposal containers.

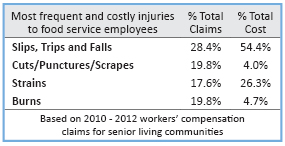

Preventing Injuries to Food Service Employees

Every year, Church Mutual senior living customers report more than 500 injuries to their employees. One occupation needing specific risk management attention is food service employees.

Employees in this category include chefs, cooks, dieticians, dishwashers, kitchen aides and similar support staff. Past claims provide insight into key safety issues to help prevent similar injuries. Use the following guidelines to help evaluate, develop and implement good risk management practices and procedures for food service employees:

Slips, Trips and Falls

- Greasy or wet floors can lead to slips and falls. Immediately clean up spills and mop floors regularly.

- Properly store all products and supplies to eliminate clutter.

- Require all employees to wear slip-resistant footwear.

- Ensure that nonskid floor mats are used in wet locations and that mats lay flat.

Cuts, Punctures and Scrapes

- Teach employees how to properly handle, use and store knives.

- Unplug slicers, mixers, blenders and similar machinery before cleaning.

- Require cut-resistant gloves be worn when cutting.

- Do not use hands or feet to manually compact trash.

Lifting Strains

- Instruct employees about proper body mechanics and lifting techniques.

- Arrange work areas so materials are within convenient reaching or lifting distances.

- Organize storage areas to stock heavy items on lower shelves.

- Provide material-handling equipment, such as carts, to limit lifting and carrying objects.

Burns

- Require employees to use hand protection, such as oven mitts, when handling hot pans.

- Teach the “standing-to-the-side” method when opening ovens and automatic dishwashers to allow steam to escape.

- Instruct employees to never carry or move containers containing hot oil or boiling water.

- Allow fryers and hot cooking pots to cool before performing cleaning procedures.

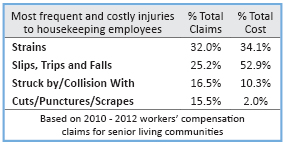

Preventing Injuries to Housekeeping Employees

Every year, Church Mutual senior living customers report more than 500 injuries to their employees. One occupation needing specific risk management attention is housekeeping employees.

Employees in this category include those whose primary job is cleaning or light-duty janitorial. Past claims provide insight into key safety issues to help prevent similar injuries. Use the following guidelines to help evaluate, develop and implement good risk management practices and procedures for housekeeping employees:

Lifting Strains

- Instruct employees about proper body mechanics and safe lifting techniques.

- Institute a team lifting policy when carrying tables or handling large, heavy or bulky items.

- Supply easy-to-use vacuum cleaners that have adjustable handles and are lightweight.

- Plan the day’s workload. Perform heavier tasks at the beginning of the work shift before fatigue starts.

Slips, Trips and Falls

- Arrange furniture, telephone and electrical cords and supplies to minimize slip-and-fall hazards.

- Require all employees to wear slip-resistant footwear.

- Train employees on the proper use of mops and other cleaning equipment used to maintain floors.

- Promote safe handling of materials. Do not carry objects that block vision.

Struck by or Collision With Objects

- Place mirrors at corners or other visually obstructed areas to help reduce collisions.

- Maintain clutter-free storage areas. Always return cleaning equipment to their proper storage location after use.

- Clearly mark and define walkways. Keep carts out of hallways when not in use.

- Mark or pad obstructions that cannot be removed to help reduce the possibility of direct contact or injury if contact occurs.

Cuts, Punctures and Scrapes

- Focus attention on the work being performed. Inattentiveness is a top cause of lacerations.

- Require employees to wear personal protective equipment. Make gloves available where appropriate.

- Dispose of used needles promptly in appropriate sharps disposal containers.

- Do not use hands or feet to manually compact trash.

For a complete collection of the Risk Alert for Senior Living Communities series, click here.